OX2 is the leading developer of onshore wind in Europe. As an industry pioneer, we are active in eleven markets and offer fully customised renewable energy solutions involving several technologies, including wind and solar energy, in addition to hydrogen and energy storage projects. We design and build sustainable projects and tailor them to meet our customers’ needs. OX2 has a proven business model and in-house expertise at every step of the process – from project inception and financing to engineering and design, permitting, procurement, construction, and technical and commercial management. Our mission is to accelerate access to renewable energy. We see ourselves becoming the leading provider of renewable energy solutions globally, thereby powering the great shift.

BESS facilities generally use lithium-ion to store the electricity until it is ready to be distributed to the network. BESS facilities allow energy generated from another source (such as a wind farm) to be stored until it is needed. BESS facilities improve grid reliability by storing low-cost electricity when there is an oversupply of electricity or during periods of low demand/high generation so that electricity is available when demand is higher. In fact, BESS can reduce electricity costs for communities by lowering peak demand charges and providing access to cheaper off-peak electricity. The BESS's fast response capability also provides ancillary services to maintain grid power quality at a standard level. Additionally, BESS can act as a backup power source during emergencies like bushfires, ensuring that critical infrastructure (hospitals, emergency services, water systems) remains operational even if the grid is disrupted.

BESS facilities contain several key components, including battery units, inverters and transformers. The final composition of a BESS facility will depend on the BESS technology used, the BESS supplier, and the facility's size. Where possible, BESS facilities are co-located with or near a grid connection point (such as a terminal station), therefore minimising the need for additional connection infrastructure.

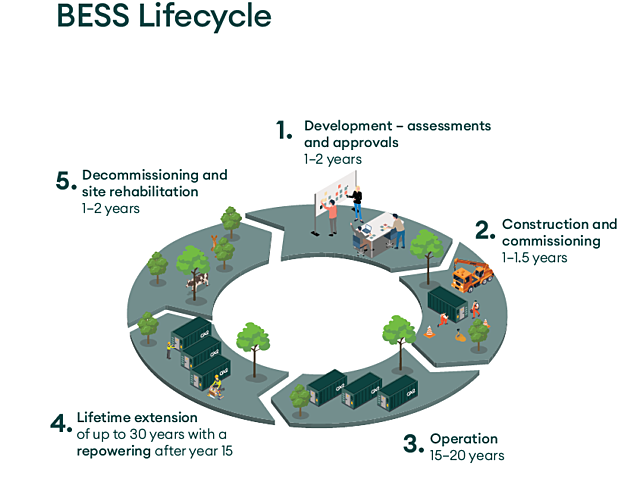

Large-scale BESS facilities are expected to have an operational life of approximately 15 to 20 years and are typically monitored remotely, without the need for permanent on-site staff. Staff are, however, required to access the site from time to time to undertake inspection and maintenance activities.

BESS facilities are typically a group of containers storing battery systems inside. The number of containers depends on the batteries being used and the space available at the site. However, BESS technology is continuously evolving, with BESS components becoming increasingly more efficient and compact in size.

A BESS design is led by site investigations, environmental assessments, community feedback and planning permit requirements. We consider a range of aspects:

• Local topography

• Geotechnical (ground) conditions

• Proximity and connectivity to the grid

• Safety

• Constructability

• Relevant standards, guidelines and legislation

• Stakeholder and community feedback

• Transport routes and access to the site

• Potential environmental and heritage impacts

• Operations and maintenance requirements

• Project cost and value for money

As the grid of the future is developed in Australia, the Australian energy market has evolved from the previous baseload power system to a more flexible system. Energy storage plays a crucial role in balancing this system. Pumped hydro is an example of long-term storage, ideal for storing energy and releasing it over periods of days or weeks. However, due to its slower ’ramping’ time, it is less effective in providing rapid-response services during grid emergencies like outages or heat waves (when air conditioning causes high demand). This critical short- erm need is fulfilled by battery storage technology.

Technical and environmental studies are undertaken by independent consultants who are experts in their field to identify baseline conditions and possible impacts. We use these studies to inform the project design, planning and construction and ongoing management. The assessments undertaken for a renewable energy Project typically include:

Like any major infrastructure project, construction of a large-scale BESS can be disruptive at certain times. To minimise this, we work with the project landowners, neighbours, contractors, local councils and wider community to plan construction responsibly and manage any impacts effectively and efficiently. Some of the ways we do this include:

Each stage of construction can pose different challenges, such as traffic movements during the initial road construction phase or over-dimensional vehicle movements as components are delivered to the site. Adequate stakeholder engagement and early planning will allow those movements to occur safely for the workforce and the community, with any planned disruptions communicated to relevant stakeholders (including the community). Depending on the size of the project, construction can take several years. Management Plans are required to outline how potential impacts are managed, and that all management and mitigation measures are understood and followed by the project partners.